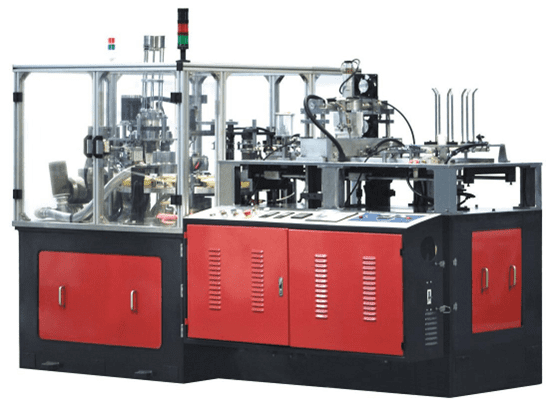

Gietz FSA 870 Compact

The FSA 870 Compact is used in the print

finishing of folded boxes, for example in the

Food area (chocolate, confectionery) or the Nonfood area (cosmetics), as well as in the print

finishing of printed matter (labels, book covers,

greeting cards or magazines). The FSA 870

Compact is also the machine of choice for many

companies in the Security industry. These Gietz

machines have proved their worth over decades

for the application of registered and hologram

patches and non-registered hologram stripes onto

banknotes, official documents and in the field of

trademark protection.

1. Reliable, fast, precise

The FSA 870 Compact is renowned for its registration accuracy, the excellent quality of the foil stamping and high production speed.

2.Short change-over times

Easy access to the foils and stamping dies, which can be quickly replaced and positioned.

3.150 metric tons of pressure

Maximum pressure at full production speed for the highest level of added value in the foil stamping and embossing process.

4.Dwell time

Due to a mature press mechanism, the dwell times under pressure of the Gietz machines remain unique. As standard, the FSA 870 Compact offers a dwell time that is 25% longer than that of our competitors. This results in lower foil stamping temperatures and less pressure is required. The dwell time can additionally be extended up to a maximum of 2.5 seconds: e.g. for deep, large surface area foiling and embossing.

5. Longitudinal and transverse foil feed

The foil can be fed through the machine in line with the sheet running direction, and/or transverse to it

6. Foil unwinding

Diameter-controlled or externally regulated foil unwinds with pneumatic brake for 1″ and 3″ cores guarantee a precise and smooth foil feed.

7. Hologram application technology

For the application of single-picture holograms for the security industry, Gietz is long established as a well-proven supplier of industry leading technologies.

8. Core competence and service life

Since more than half a century, Gietz has focussed on foil stamping, and Gietz machines are first and foremost designed as foil stamping and embossing systems. User experiences with hundreds of machines have been consistently incorporated and integrated into their design. A Gietz is a Gietz: it foil stamps and embosses giving the highest quality, often for more than 20 years before requiring the first overhaul.

9. Price-performance ratio

The very highest stamping quality, maximum production speed, extremely long service life and reliability. A Gietz machine is well worth its price.

10. Top products for professionals

Foil stamping machines from Gietz are recognized by printers worldwide as industry leading products from professionals for professionals.

• Sheet format:

max. 870 x 560 mm / 34.3″ x 22.0″

min. 280 x 210 mm / 11.0″ x 8.3″

• ESS special format:

max. 870 x 600 mm / 34.3″ x 23.6″

• Material thickness:

max. 2 mm / 0.08″

min. approx. 70 g/m² / 0.003″

• Stamping area: max. 800 x 520 mm / 31.5″ x 20.5″

ESS max. 800 x 592 mm / 31.5″ x 23.3″

• Speed: max. 6000 strokes/h

• Temperature up to 180 °C / 356°F by 6

individually controllable heating zones

• Pressure of the press: max. 150 tons / 165 US tons

• Foil webs: max. 6 (more on request)

• Foil core diameter: 3″ and 1″

• Foil reel diameter: max. 210 mm / 8.3″

• Foil width:

max. 805 mm / 31.7″

min. 25 mm / 1.0″

• Pile height

At feeder side: max. 1120 mm / 44.1″

At delivery side: max. 850 mm / 33.5″

• Weight and dimensions

Weight: approx. 8 tons / 8.8 US tons

Base: approx. 4.0 x 2.8 m / 13.1″ x 9.2″

Height: 2.3 m / 7.6″