A-330 PAPER BAG MAKING MACHINE WITH TWISTED HANDLE

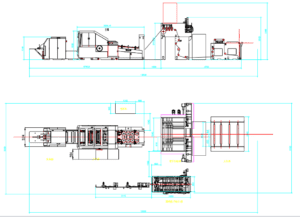

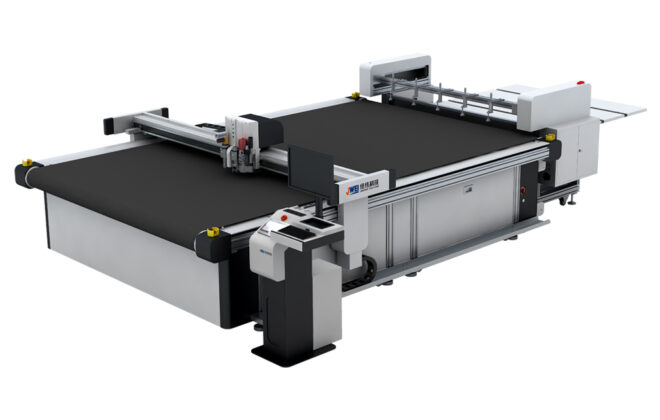

A330 full automatic square bottom paper bag machine is used for the production of a paper bag with a twisted handle loop. Transmission of the handle made by handle making unit, cut, stick, pressed, and then pre-cut, glue, auto handle stick in empty or printed roll paper. Then the main machine will glue the paper with the handle loop to the edge, paper bag tube forming, cut off, indentation, bottom glue, bottom forming, and sealing, bag conveying. the whole process is completed simultaneously at one time. Real realization of full automation production, can effectively save labor costs.

The whole machine adopts the servo-electric control system imported from Japan, which ensures the whole machine can run quickly and stably and effectively reduces the time of paper bag size adjustment. The finished bags produced are of high accuracy, strong stability, simple maintenance, and efficient production, which is the ideal equipment for major printing plants and paper bag manufacturers.

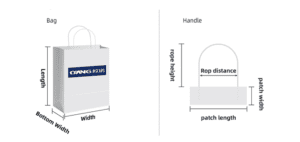

FINAL PRODUCT

PRODCUTION RANGE DESCRIPTION

| Paper roll width | 490/590-1050mm |

| Paper diameter | ≤1500mm |

| Core inner diameter | Φ76mm |

| Paper weight | 80-140g/m2 |

| Paper bag width | 200-330mm with handle |

| 150-330mm without handle | |

| Paper tube length | 280-430mm With handle |

| 280-530mm Without handle | |

| Bottom width of paper bag | 80-180mm |

| Machine speed | 150pcs/min |

| Total power | 32KW |

| Machine weight | 16000KG |

| Machine dimensions | 14000*6000*3500mm |

HANDDLE PRODCUTION RANGE DESCRIPTION

| HANDLE MODEL | 5HD |

| Handle rope height | 95-115mm |

| Handle patch width | 45-50mm |

| Handle patch length | 152.4mm |

| Handle rope diameter | Φ4-6mm |

| Diameter of handle patch paper roll | Φ1200mm |

| Handle patch paper roll width | 90-100mm |

| Handle patch weight | 100-140g |

| Distance of the handle | 76mm |