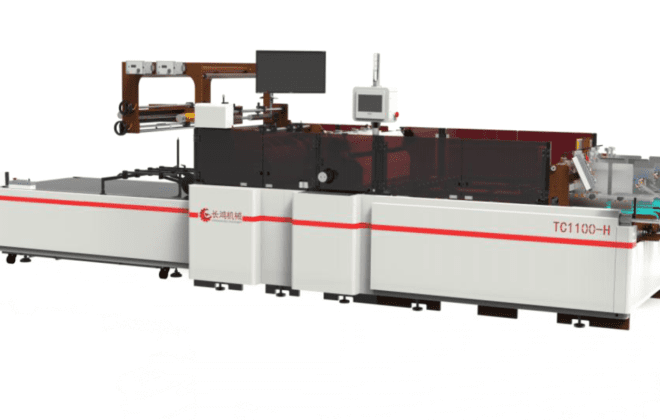

Maschine zum Formen von Papierbechern

| Capacity | pcs/min | 100-120 (according to the cup size and raw material) |

| Size range | mm | Top Diameter:50-110mm

Bottom Diameter:40-70mm Height:40-138mm |

| Suitable paper thickness | gsm | 135-450 |

| Sealing method | Ultrasonic & hot air system | |

| Running Power | KW | 12 |

| Air compressor | 0.4 M³/Min 0.5MPA | |

| Net weight | kgs | 3400 |

| Machine dimension | mm | 2500×1800 ×1700 |

| Collector dimension | mm | 900 ×900 ×1760 |

Our factory is the first one using two cam systems, this design more costly, but can let the top curling and bottom knurling more accuracy, stable and low noise.

Cam adopts high strength Japan-SKD11 with quenching treatment, resistant to wear. Before set up on the machine, our factory will test running one week, to ensure each bearing at the suitable station.

This system ensure the machine runs with high speed with low noise, smoothly running and high precision. Instead of chain drive.

2 set of hot air systems can decrease the rate of leakage. Our factory using the whole set of Leister(Banko) hot air system with protection system. And our system sets up on the fixed plate, do not moving during production. Almost impossible to damage.

Also the only one have the protect system that hot parts will go down, keep the distance with paper cup and cup mould when the machine stop.

Unique design. Our factory set up on final turn station, more stable than set up on flying tube. Do not need to buy extra inspection machine, less factory space needed. Inspection accuracy can be set up by self.

Adopts forced lubrication system to ensure main driving oil supply regularly and reduce friction and prolong the machine life. The oil circuit adds a clear the oil and filtering system to clean the oil automatically. Our factory is the first one to using double layer plate to avoid the scraps of paper into the machine’s inside.

Controlled by simple and efficient PLC system

Hot air system for preheating, using ultrasonic for side seal. Ensure no water leakage during high speed running. Especially for double PE coated paper fan, have two side hot air system. Ultrasonic is made in Taiwan by EVEN GREEN.

Each production step have camera. Any step have problem will be showed on PLC. Such as the stock of paper fan less than standard, will be alarming. If do not add paper fan, will finish paper fan in machine firstly, then, stop the machine automatically.

Service for bottom paper feeding. The feature of runs more stable and accuracy, reduce the waste of bottom paper. Servo motor is made in Japan by MITSUBISHI.

Unique design for bottom paper cutted as a piece of paper, easy to pack. Our factory set up length. Easy to package as tube

Our factory also the one have air controller, and the only one set up two air blowers on the machine. Less air consumption required and avoid the cup fall off during production.

Set up after the side sealing, when the cups finished cup side sealing, can fix the cup position. And the fans are foldable, when you change the paper fan thickness and adjustment, it is easy to take the cups out.

Our factory special design for paper fan delivery. A lot of small ball at the bottom, instead of chain or block, can efficient avoid paper fan jam.

Add the air cylinder at this parts, have control panel. When worker change the roller, just need to adjustment the height of holder, do not need to move the roller up.As a woman, also easy to change the roller.

Set up safe door and security button. Keep safe. Two type of design can be selected.